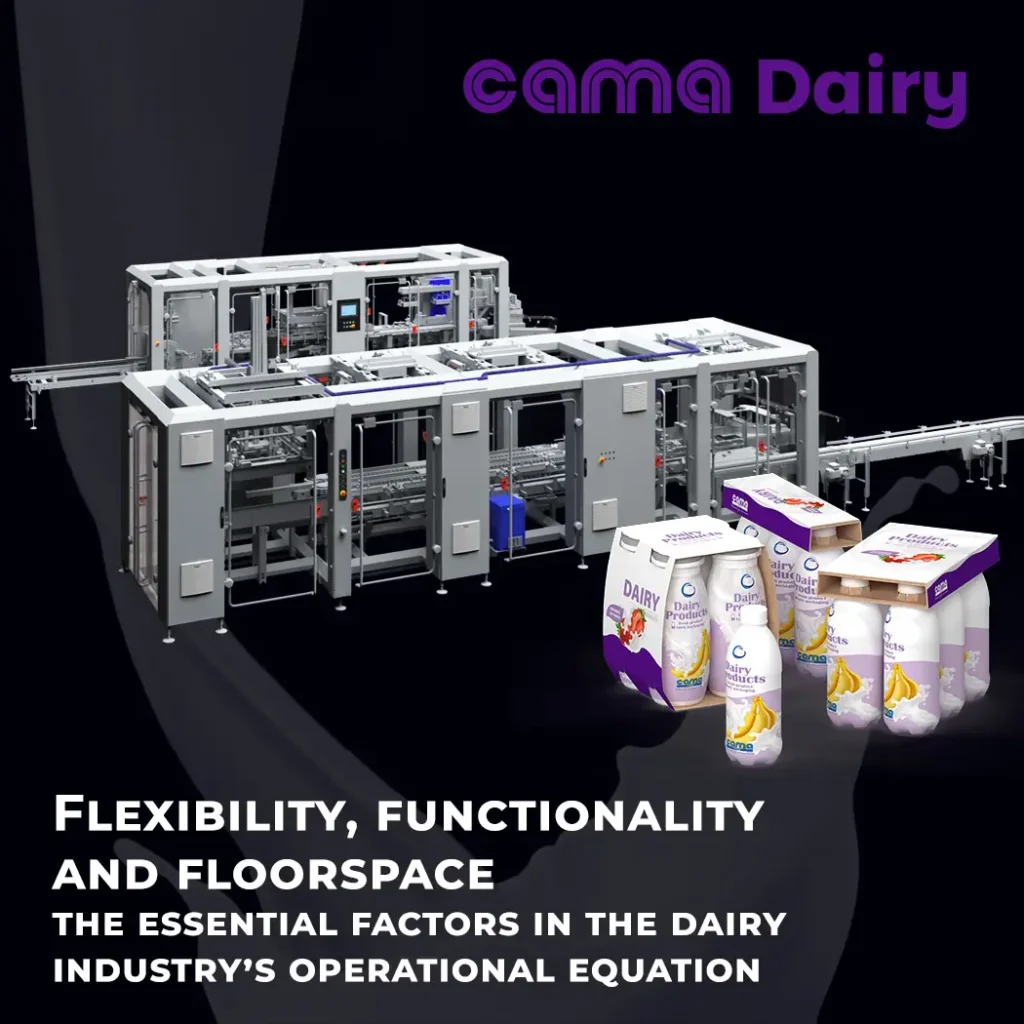

Flexible packaging systems meet the evolving demands of the dairy industry with automation, rapid changeover capabilities and compact design

The dairy industry has undergone a remarkable transformation. A decade ago, product variety was limited, with standardized portions and basic packaging formats. Today’s supermarket shelves showcase an extensive array of dairy products—multiple flavors, portion sizes, dietary options and innovative packaging styles—as brands compete for consumer attention in an increasingly competitive marketplace.

While this product diversification represents an effective marketing strategy and manageable production challenges, it creates significant complexity for end-of-line operations. Secondary packaging machines must accommodate diverse product counts, formats, portion sizes and flavors while maintaining the flexibility to adapt as market demands continue to evolve.

The flexibility imperative in dairy packaging

David Andry, dairy key account manager at Cama Group, explains the current landscape: “End-of-line technologies face real scrutiny regarding their operational capabilities. Our customers exhibit understandable concerns because product requirements can change rapidly. Companies need flexibility and agility in their packaging technology and technical partnerships—not just for current needs, but for products they may launch in the coming months.”

The era of dedicated single-product packaging machines has ended for most dairy operations. Modern packaging systems must handle diverse products, counts, sizes and flavors. Equally critical is the ability to change tooling between batches quickly and efficiently. Even the most flexible packaging machine loses value if changeover downtime impacts overall productivity.

Space optimization challenges in dairy facilities

Many dairy producers operate facilities located near population centers, making expansion difficult. This constraint requires maximum efficiency from available floor space. As packaging equipment suppliers, Cama Group consistently delivers optimum performance and flexibility within compact footprints.

“Our compact and monobloc machines have gained popularity precisely because of their space-efficient design,” notes Andry. “The modular construction and flexible access points make them ideal for limited floor space. We can configure systems with single-side access and even design around corners. Combined with adaptable utility feeds and product in-feeds, these solutions address numerous space-conscious requirements.”

Performance optimization: balancing speed with versatility

Operational performance remains essential in dairy production. Uptime and throughput represent critical metrics, but flexibility and high availability mean little without adequate processing speed.

Cama Group’s packaging machines exemplify this balance. For example, systems can package four-packs of yogurt in wraparound sleeves and load them into family-size cartons. With simple adjustments, the same machine deploys a bypass conveyor to package 48 individual pots into cases for single-serve lunch purchases—all at high speed with minimal reengineering between batches. The following day, the system can handle eight-packs or sixteen-packs with equal efficiency.

Advanced technology enables intuitive operations

Rapid changeover capabilities stem from intuitive machine access and clear instructions delivered through AR and VR technologies. RFID part identification ensures correct components are installed at the appropriate time for specific machine and batch configurations. Throughout a production shift, these immersive technologies can save significant downtime—minutes or even hours.

This intuitive approach also simplifies operations, reducing dependence on highly specialized workers. The need for user-friendly interfaces extends beyond workforce skill levels. Many dairy producers face the challenge of senior engineers retiring and taking institutional knowledge with them.

This knowledge gap has driven development of Cama Group’s HMI solutions and expanded the company’s consulting role across business operations, including popular packaging design services. Just as products influence downstream processes, packaging and sustainability considerations affect upstream decisions. Cama Group’s sector expertise positions the company to provide valuable insights ensuring customers account for all variables throughout their operations.

Financial considerations: OpEx versus CapEx

Investment decisions should not be driven solely by capital expenditure. Even basic calculations demonstrate that fast, flexible and efficient packaging machines deliver faster payback than less expensive alternatives. When factoring in uptime, throughput, waste reduction and packaging flexibility, operational costs become far more relevant than initial purchase price.

Elevated overall equipment effectiveness (OEE) translates to significantly lower total cost of ownership (TCO). Companies that prioritize operational excellence recognize that premium technology investments generate superior long-term value.

Real-world application: medicinal dietary drinks project

A recent project for a leading global dairy company illustrates these principles in action. The application involved packaging 125ml bottled medicinal dietary drinks at rates of 720-750 boxes per minute, with nominal speeds of 650 ppm. The system also handles 200ml and 250ml bottle formats.

The production process begins with bottles receiving PET shrink sleeves before an automatic divider sorts them into two lanes. A belt system then feeds 24-product and 32-product arrays. Alternatively, bottles can be diverted into different modules for packaging in four-pack or six-pack clusters. Two print-and-apply labelers handle box labeling, while cardboard blank magazines utilize Cama Group’s collaborative robot solution for loading.

The turnkey package integrates third-party shrink sleeve equipment, labeling systems, X-ray inspection and code application/reading technologies—demonstrating Cama Group’s comprehensive solution capabilities.

Innovation leadership in dairy packaging automation

Cama Group maintains its position at the forefront of dairy industry innovation. From simple advances like the new tray/hole solution for dairy lines to cutting-edge Industry 4.0 capabilities, the company’s technologies integrate seamlessly with digitally transformed operations and existing infrastructures.

“Behind all our technological solutions are our people,” emphasizes Andry. “They deliver the support our customers need at every stage of the value chain, fostering close business relationships that drive mutual success.”

Sustainable packaging solutions

Sustainability represents a core consideration in modern dairy packaging operations. Cama Group designs environmental responsibility into every machine and packaging solution. Lower energy consumption, reduced waste, optimized packaging design and recyclable or reusable materials form essential elements of the company’s approach.

The dairy sector increasingly demands lighter, more environmentally friendly packaging. Single-material packaging concepts are emerging, where tubs, lids and secondary packaging comprise the same recyclable materials. This transition requires packaging partners who understand both current requirements and future sustainability trajectories.

Key takeaways for dairy packaging excellence

Modern dairy packaging operations require:

Flexibility: Systems that handle multiple formats, counts and product types with minimal adjustment

Speed: Rapid changeover capabilities that minimize downtime between batches

Efficiency: Compact footprints that maximize performance within limited space

Technology: Industry 4.0 integration with AR/VR training and RFID tracking

Sustainability: Environmental responsibility through reduced waste and recyclable materials

Partnership: Technical expertise and consulting support across the entire value chain

Discover flexible dairy packaging solutions

Cama Group delivers comprehensive packaging automation for the dairy industry, from individual machines to complete integrated lines. Our solutions combine operational excellence with the flexibility modern dairy producers require.

Contact our dairy packaging specialists to discuss how our flexible, efficient and sustainable packaging systems can transform your dairy production operations.